To get to the top, we dive as deep as possible

In the search for oil, we find ways to continuously transform the Exploration and Production (E&P) market on high seas (offshore) and on land (onshore). Our focus is on seeking profitable assets in deep and ultra-deep waters, to ensure our country's energy security as well as its supply.

In order to do this, we joined forces with major global energy players to create new projects and we have invested in technologies and teams with technical excellence. Our Oil exploration and extraction is, above all, a way of creating a better future for everyone. Dive in with us and find out how!

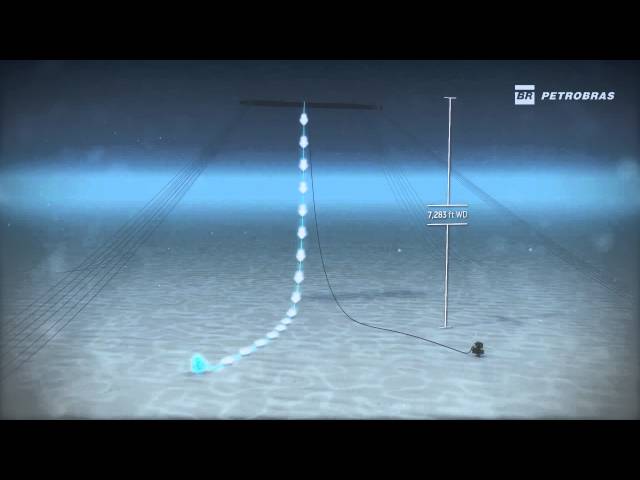

But, after all, how oil is extracted offshore?

1. Exploration

In the O&G industry, exploration and production are essencial for business. And it all starts with acquiring the exploration rights of some area. In Brazil, oil exploration contracts are governed by three Regulatory Frameworks: concession, production sharing and transfer of rights.

With this in hand, we begin studying the area through geological and geophysical assessments. And we go deep: our geoscientists analyze everything from the local tectonic movements and the behavior of fluids—oil, gas, and water—in the reservoir, to the characteristics of the region’s rocks, to understand how and when they were formed. Once all this is done, we use advanced technology to identify the most likely locations to find oil and the ideal positions for a first well.

2. Production Development: we study the past to define the future

At this stage, we begin planning and contracting the production systems, including platforms, subsea systems, drilling and interconnection of wells, and more.

By evaluating natural, maritime, and economic variables, new questions and decisions arise: how many wells will be drilled? What will be the best artificial lift system to use? What type of platform will be installed?

After planning and executing these details, we start oil production.

3. Production: where the magic happens

And what happens when a production system comes to an end?

Where does the Petrobras oil come from?

A true giant of the seas

It is because of the Campus Basin that we are currently world leaders in technology for exploration and production in deep and ultra-deep waters. The region is one of the main and most productive offshore oil and gas basins in the world since the 1970s, and we have the power to grow much more.

It was the birthplace of several innovations that revolutionized the global market and that put our name on the list of the largest and most innovative offshore oil and gas producers in the world.

We have the largest oil extraction basin in Brazil

The Santos Basin has always been ahead of its time. Our first activities in the region began in the 1970s, but the technology and knowledge of the time limited our oil production potential. The solution, then, was to pause our operations and develop our own pioneering technologies and establish partnerships.

Decades later, we returned to invest in drilling and well production in the Santos Basin. In 2009, we produced the first pre-salt oil in the Basin, which currently comprises the largest producing fields in the country, such as Tupi and Búzios.

Check out some of the main oil fields in the Santos Basin

This result is due to the high productivity per well in Búzios, the evolution of knowledge accumulated in the pre-salt fields and the use of state-of-the-art technologies developed to increase the efficiency of the reservoirs.

Tupi & Iracema is more than just a field! It is a symbol of innovation, partnership, and the Brazilian ability to overcome challenges and achieve historic milestones in the pre-salt.

It was a pioneer in the use of new technologies recognized by the industry—a total of nine technologies awarded worldwide by the OTC (Offshore Technology Conference).

Its reservoir is highly productive and has been increasing its share in our portfolio, a trend that will continue in the coming years.

National presence that becomes a world reference

We explore in search of new discoveries

FPSOs: the ultimate and most modern oil production system

After extraction, the oil needs to go through a process for treatment, collection and shipment to logistics terminals. With the creation of FPSOs, all of this is done at high seas.

FPSOs are floating production, storage and transfer units, and their acronym means: Floating, Production, Storage and Offloading. As they do not require the installation of oil pipeline infrastructure, because they transfer oil to tankers, FPSOs have become the most efficient and modern alternative to supply the energy demand.

Use of FPSOs to explore pre-salt and produce cleaner oil

The pioneering spirit of the units is also focused on sustainability. A growing number of Petrobras FPSOs already use CCUS and Hisep technologies to separate CO2 from extracted oil and reinject it directly into the soil. This process considerably reduces the release of greenhouse gases (GHG) into the atmosphere, and it also increases the productivity of oil wells.

We explore ideas to produce a more sustainable future

Brazil possesses all the necessary conditions to be a global pioneer in the fair, inclusive and sustainable energy transition. And Petrobras possesses all the necessary conditions — and the plan — to lead this journey in Brazil. Our commitment is to seek continuity in improving the carbon efficiency of our E&P activities.

Since 2009, we have already achieved a 50% reduction in the intensity of GHG emissions in E&P activities. This result comes from actions related to improvements in energy efficiency, reduction of losses and greater use of gas with reduced flare burning, in addition to improvements in accounting and inventory of emissions.

All Electric: This concept represents the new generation of our FPSOs. The fully electrified floating units are even more energy efficient than traditional FPSOs and reduce greenhouse gas emissions by up to 20%. Our purpose is to electrify all platforms in the coming years.

World's Largest CCUS Program: We are leaders in CO2 capture, utilization and geological storage (CCUS). The exclusive technology reinjects the gas into the reservoir and prevents release into the atmosphere. In 2022, we reached the record of 25% of the total injected by the global industry: 11 million tons!

Energy transition and security are priorities for the global energy industry

Our purpose is to minimize not only the environmental impacts of our activities, but also social impacts. Therefore, we use the most modern technologies in new frontier areas. After all, a digital and data-driven operation not only allows for the construction of better predictive models and greater predictability, but also increases efficiency, boosts results and reduces the carbon intensity of operations.

We expanded our E&P areas and transformed our operations to ensure that everyone has opportunities to access energy, considering cost, distribution infrastructure and a minimum adaptation time.

In this sense, our strategic planning sees the new E&P frontiers as fundamental activities to meet energy demand, while providing resources for a fair, safe and accessible transition in low carbon energy generation.

Glossário - teve dúvida em algum termo? Te explicamos abaixo

You may be interested in

Do a search:

Search suggestions

Most searched

Fuel price

Pre-salt

Team Petrobras

Choose a channel:

Browse the Sections:

Accessibility

Language:

Select a language: